Success in the manufacturing industry requires that you produce the right products, in the right quantities, at the right time, with good quality, and at a price the customer is willing to pay. The flexibility to respond to compliance standards and the ever-changing needs of customers, such as providing real-time visibility into global operations, is also imperative for success. Meeting these demands requires the ability to make quick decisions based on accurate data. Microsoft and its partners deliver systems that can help you improve operations, open visibility into the supply chain, and increase your competitiveness.

Microsoft Dynamics AX can help streamline processes and minimize the costs of carrying inventory for firms that produce goods from raw materials.

Lean Manufacturing for Microsoft Dynamics AX

Lean Manufacturing for Microsoft Dynamics AX can help manufacturing organizations implement, energize, and sustain lean manufacturing initiatives by delivering the tools and information support needed to streamline processes, reduce waste, enable demand-pull operations, and promote continuous improvement. As part of Microsoft Dynamics AX, robust lean manufacturing functionality complements the solution’s comprehensive customer relationship, financial, collaboration, and supply chain management capabilities to help manufacturers increase efficiency and profitability and gain a competitive advantage.

This functionality is delivered as an integral part of a flexible and familiar end-to-end business management solution complete with the business insight and collaboration tools you need to sustain lean manufacturing and gain a competitive advantage.

Apparel and Textile for Microsoft Dynamics AX

Apparel and Textile for Microsoft Dynamics AX can help you address the complex coding, traceability, and changing process needs of apparel and textile manufacturers—from fibers to yarns, consumer and industrial fabrics, home goods, clothing, designer lines, and fashion accessories. If you can satisfy demanding customers and sustain agile businesses, you are better equipped to stay ahead of global competition, manage complex supply networks, and handle ongoing mergers and acquisitions.

Apparel and Textile for Microsoft Dynamics AX

Apparel and Textile for Microsoft Dynamics AX is designed to address complex coding, traceability, and changing process needs of apparel and textile manufacturers—from fibers to yarns, consumer and industrial fabrics, home goods, clothing, designer lines, and fashion accessories. With the ability to satisfy demanding customers and sustain agile businesses, you are better equipped to stay ahead of global competition, manage complex supply networks, and handle ongoing mergers and acquisitions.

Apparel and Textile for Microsoft Dynamics AX is designed to address complex coding, traceability, and changing process needs of apparel and textile manufacturers—from fibers to yarns, consumer and industrial fabrics, home goods, clothing, designer lines, and fashion accessories. With the ability to satisfy demanding customers and sustain agile businesses, you are better equipped to stay ahead of global competition, manage complex supply networks, and handle ongoing mergers and acquisitions.

Traceability

Gain comprehensive traceability and handle numerous material and product variables effectively with multi-dimensional item coding.

Track materials through variable sourcing and manufacturing processes, subcontractors, inventory, and logistics, including intercompany processing.

Manage complex item variables with advanced coding attributes and "smart" stock-keeping unit (SKU) coding for raw materials, process outputs, and item characteristics.

Automatically update item codes based on manufacturing process completion with transaction-driven code changes and extensions.

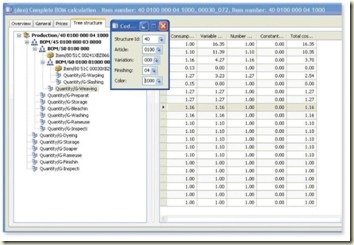

Link finished goods back to components and suppliers through item bills of material (BOMs).

Financial management

Control costs by monitoring and analyzing material, item, order, and cost information using comprehensive financial management tools.

Analyze performance and profitability across your business.

Generate multi-faceted price lists that include promotional, trade show, or showroom pricing.

Process management

Increase agility with adaptable processes for sourcing, manufacturing, and shipment allocation.

Meet changing customer and supplier requirements with blanket orders, neutral BOMs, multiline manufacturing orders, inventory double units of measure, and variable routing and allocation simulations.

Enable production and materials planning, independent of variables such as size, color, or color-way.

Run simulations and model new processes to adapt quickly to changes.

Production

Increase efficiency.

Support either push or pull production policies, and integrate subcontractor routings and management into planning and logistics.

Customer orders

Streamline order entry.

Create multiple order types, such as collection and showroom orders, and opening blanket orders with truncated codes for later specification.

Accommodate multiple shipment addresses and delivery dates per order.

Save time making mass modifications in existing or blanket orders.

Define and meet customer requirements for put-up options, labeling, unitizing, and documentation.

Speed billing and reconciliation with item and shipment information that is fully integrated into invoicing and accounting processes.

Quality assurance

Integrate quality grading processes and information into the production and supply chain.

Allocate products of various grades to different distribution channels.

Gain insight into grade costs and profitability.

Inventory management

Maintain multiple material status indicators.

Improve inventory management with comprehensive tracking of materials and finished goods.

Supply chain management

Increase supply chain visibility.

Monitor subcontractor performance, and collaborate effectively.

Incorporate supply partners into costing and routing decisions.

Share demand and inventory information in real time.

Use multicurrency, multilingual, and multisite support to speed transactions, improve transparency, and provide consolidated financial reporting to people worldwide.

Offer trade partners security-enhanced, self-service access to key business processes through familiar Web browsers.

Price lists

Access integrated cost information.

Easily generate price lists for finished goods of various quality grades, sizing, and quantities.

Create and maintain special promotional, trade show, or showroom pricing.

Units of measure and conversion